MSR/EMUX

MSR

- Cabinets are ruggedized and tested to be in compliance withMIL-STD-810G and MIL-STD-461F environmental and EMI requirements.

- Cabinets are constructed from 6082 Aluminum, making it ideally suited for both electrical conductivity and earthing through grounding bars and bonding straps.

- Cabinets are specifically designed to allow for straightforward attachment of aluminum, stainless steel, or other paneling material to its framework to create a modular cabinet.

- The aluminum framing design offers lightweight construction with heavy-duty abilities. It comprised of aluminum-extruded members, matching die-cast and forged corners, and complementary components and fixings.

- The components inside the Cabinets are COTS in their nature.

- Cabinets’ doors are hinged and can be completely removed for easy access. The doors, when closed provide protection against harsh environmental and EMI conditions.

- Cabinets are designed for easy maintenance and are easy to operate. Installation/dismantling of all components is possible by removable side panels.

- Cabinet’s design takes into account human engineering aspects to allow easy and comfortable use for technicians to maintain and operate the cabinet.

- Cabinet’s design supports three types of equipment installation:

- Equipment mounted directly on Slides.

- Equipment mounted on 19” Tray with slides.

- Equipment mounted directly on 19” infrastructure.

- For every equipment installation location, a cable retractor or other means of cable management is provided as well.

- The Cabinets will be isolated from outer shocks and vibrations by means of robust, wire-type Shock Isolators.

- Cooling is achieved by high flow fans. An optional, side mounted, closed-loop Water-cooled heat exchanger can be offered as well.

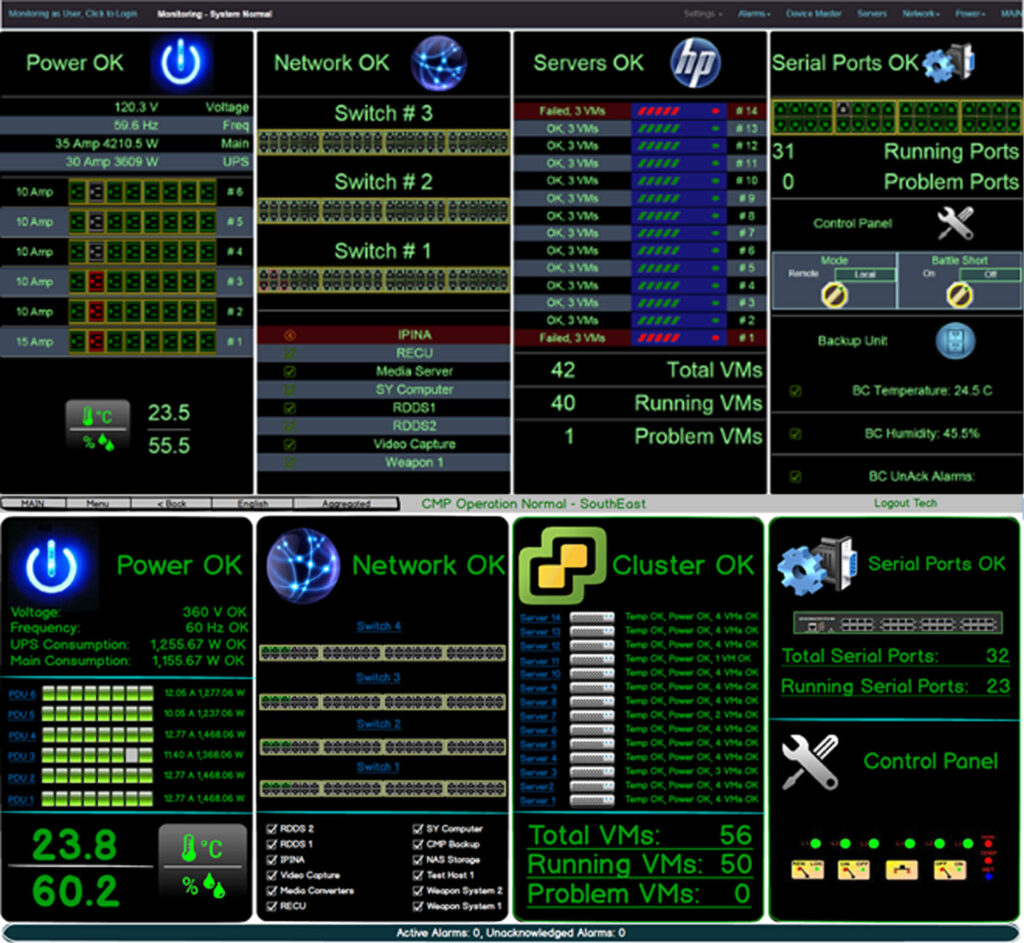

- Power is distributed via Power Distribution Units (PDU). Each Outlet on the PDU’s switched and can be externally controlled and monitored by the Cabinet Management Program (CMP) through LAN or RS-232 Serial interface.

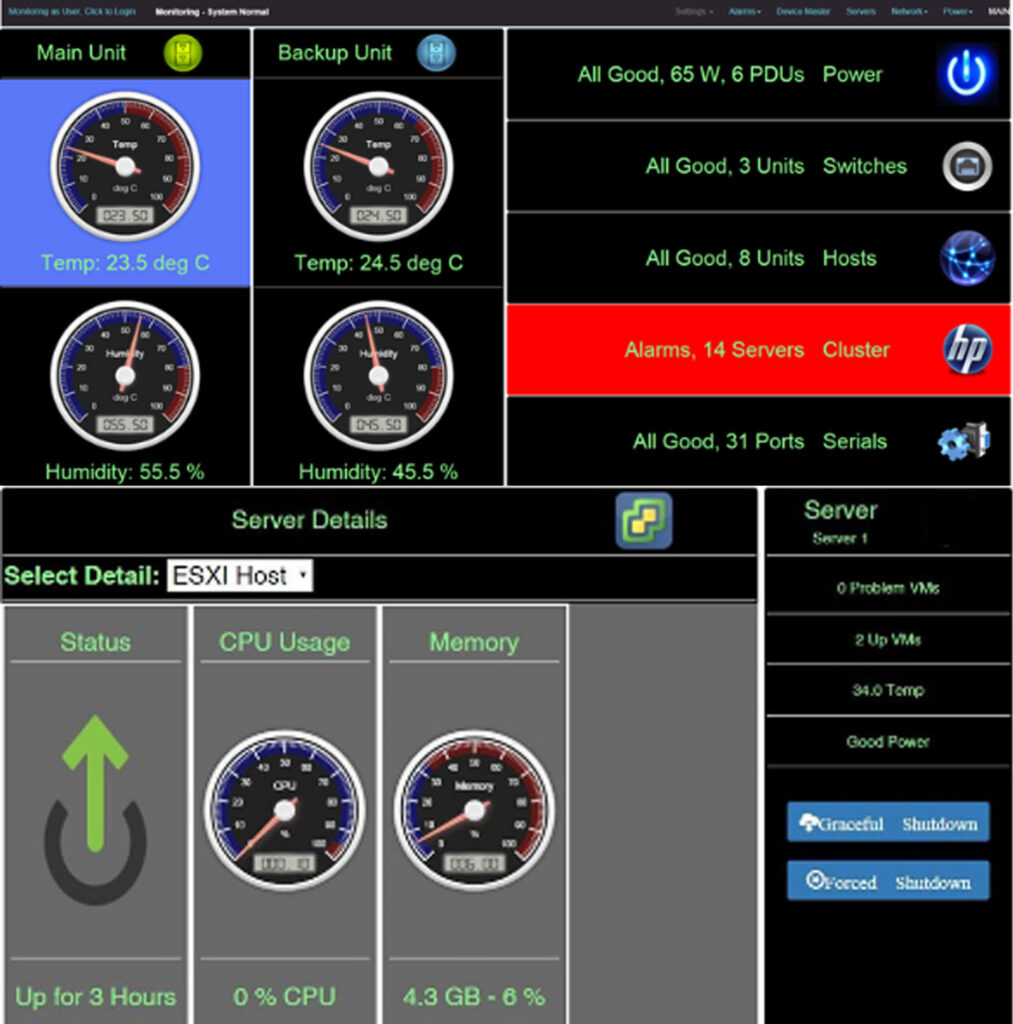

- The Cabinet is provided with an Environmental Monitoring Unit (EMU), which contains Temperature/Humidity sensors.

- All I/O interfaces are accomplished through an I/O Connector’s panel. A set of mating connectors with appropriate back-shells and strain-Reliefs can be offered as well.

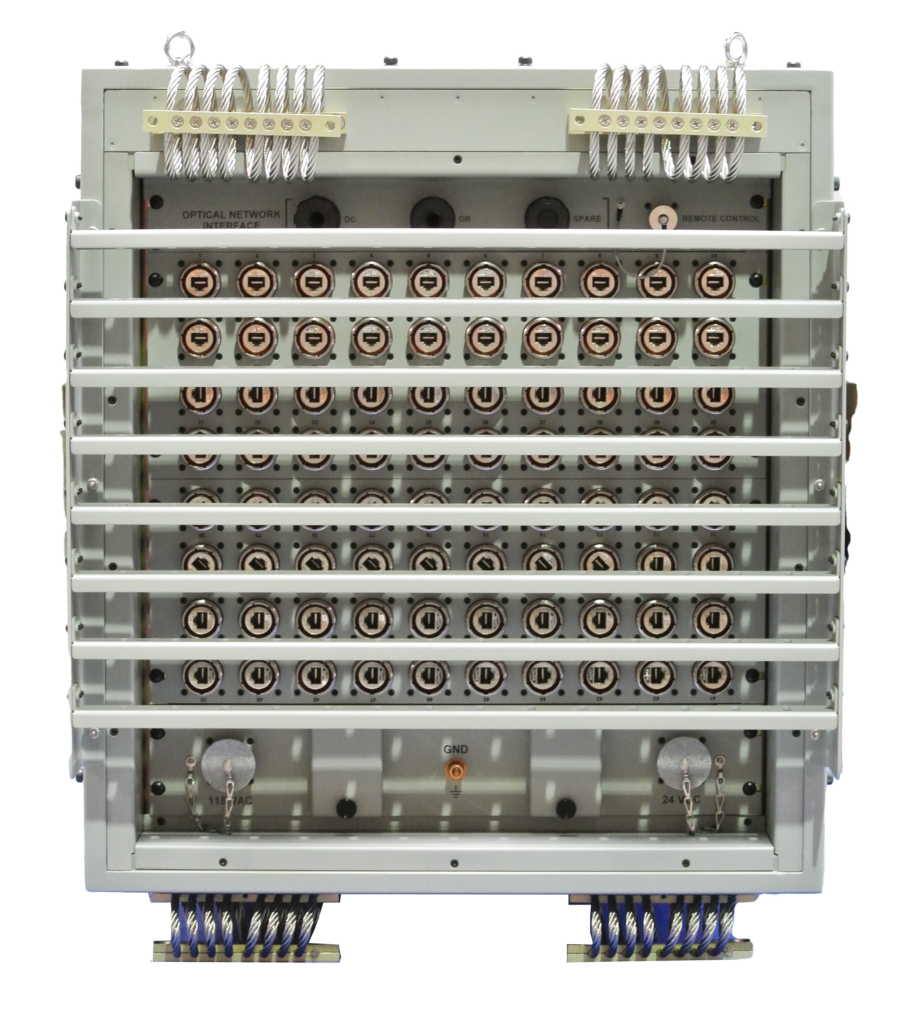

EMUX

- Ruggedized and tested to be in compliance with MIL-STD-810G and MIL-STD-461F environmental and EMI requirements.

- Constructed from 6082 Aluminum, making it ideally suited for both electrical conductivity and earthing through grounding bars and bonding straps.

- Specifically designed to allow for straightforward attachment of aluminum, stainless steel, or other paneling material to its framework to create a modular cabinet.

- The aluminum framing design offers lightweight construction with heavy-duty abilities. It comprised of aluminum-extruded members, matching die-cast and forged corners, and complementary components and fixings.

- The components inside the Cabinets are COTS in their nature.

- Doors are hinged and can be completely removed for easy access. The doors, when closed provide protection against harsh environmental and EMI conditions.

- Designed for easy maintenance and are easy to operate. Installation/dismantling of all components is possible by removable side panels. Design takes into account human engineering aspects to allow easy and comfortable use for technicians to maintain and operate the cabinet.

- Cabinets design supports three types of equipment installation:

- Equipment mounted directly on Slides

- Equipment mounted on 19” Tray with slides

- Equipment mounted directly on 19” infrastructure

- For every equipment installation location, a cable retractor or other means of cable management is provided as well.

- The Cabinets will be isolated from outer shocks and vibrations by means of robust, wire-type Shock Isolators.

- Cooling is achieved by high flow fans. An optional, side mounted, closed-loop Water-cooled heat exchanger can be offered as well.

- Power is distributed via Power Distribution Units (PDU). Each Outlet on the PDU is switched and can be externally controlled and monitored by the Cabinet Management Program (CMP) through LAN or RS-232 Serial interface.

- The Cabinet is provided with an Environmental Monitoring Unit (EMU), which contains Temperature/Humidity sensors.

- All I/O interfaces are accomplished through an I/O Connector’s panel. A set of mating connectors with appropriate back-shells and strain-Reliefs can be offered as well

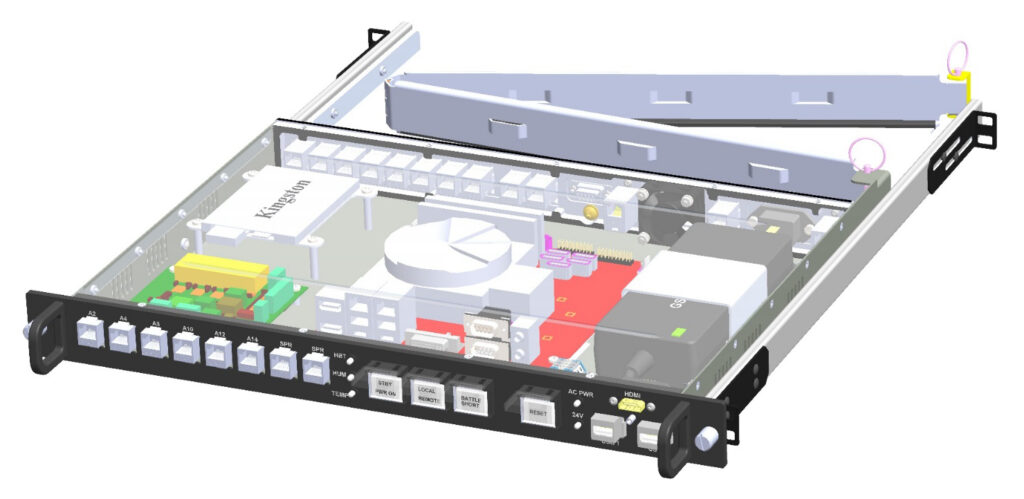

CCMU

- Power On/Off process is controlled by a Cabinet Control & Management Unit (CCMU) that is powered up as soon as the AC power source is available, and the Circuit Breaker is turned on.

- Operation is initiated through the Cabinet Control Panel (CCP). The CCP contains the switches and indicators require for starting up the cabinet’s operation.

- Cabinets are controlled and managed via on-board Cabinet Control & Management Unit (CCMU) loaded with a fully integrated Cabinet Management Program (CMP). For advanced setup, such as Network and Cyber security management, the cabinet is equipped with on-board KVM.

- The CMP software is provided fully integrated with every cabinet. The CMP monitors, controls and manages the overall operation of the cabinet’s equipment. It also provides the ability to remote monitoring and controlling of other cabinets which are part of the Data Center.

- The CMP supports three levels of operation:

- USER: Status Monitoring only. Password protection shall be required.

- TECH: Password protected and allows for modification of system parameters.

- ADMIN: Requires two levels of authentication Full access to Servers and Network Devices.

- The CMP supports three levels of operation:

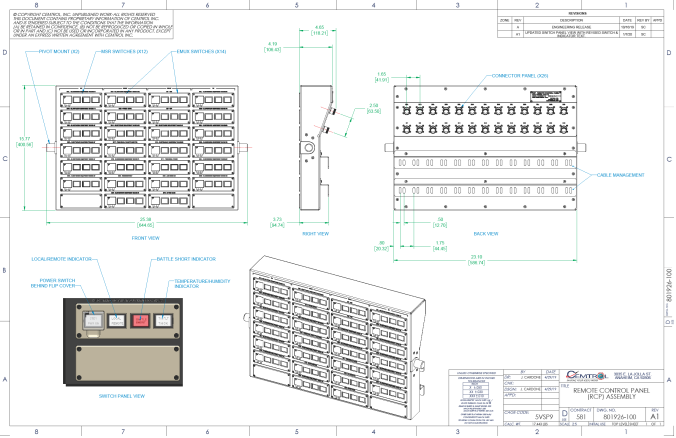

RCP

The Remote Control Panel (RCP) provides centralized location for all IT cabinets installed on the ship. It consists of Control Modules, each supporting remote control function for each cabinet. Each interfacing through dedicated Remote Control Cable. Each module is fully independent and powered up by the respected cabinet.

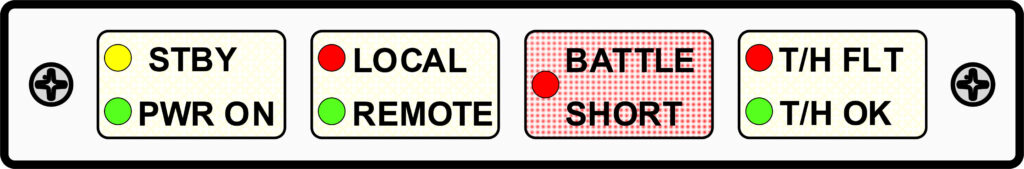

LOCAL/REMOTE Indicator

When the designated cabinet is set to Remote mode, the LED is Green and the Power On/Off switch is enabled. When the designated cabinet is set to Local mode, the LED is Red and the Power On/Off switch is disabled.

ON/OFF Switch

This switch is enabled only in Remote mode. When pressed in, the LED lits Green and power up sequence of the designated cabinet is initiated. When de-pressed, power off sequence is initiated and the LED lits Amber. To avoid accidental activation, the switch is protected by spring loaded cover. Additionally, switch must be pressed for at least 3 second to be activated.

BATTLE-SHORT Indicator

When Battle-Short Switch is activated on the designated cabinet, the LED is Red. When the switch is de-activated, the LED is off), powering up the cabinet will be permitted only if environmental conditions are within operational limits set for the designated cabinet.

T/H Indicator

When LIT red, indicates high temperature or high Humidity condition

OUR COMPANY’S MAIN FOCUS IS TO CONTINUE PROVIDING WORLD CLASS QUALITY PRODUCTS AND SERVICES TO ITS CUSTOMERS. THIS IS COUPLED WITH COMPETENT CUSTOMER SERVICE.

CEMTROL 2021