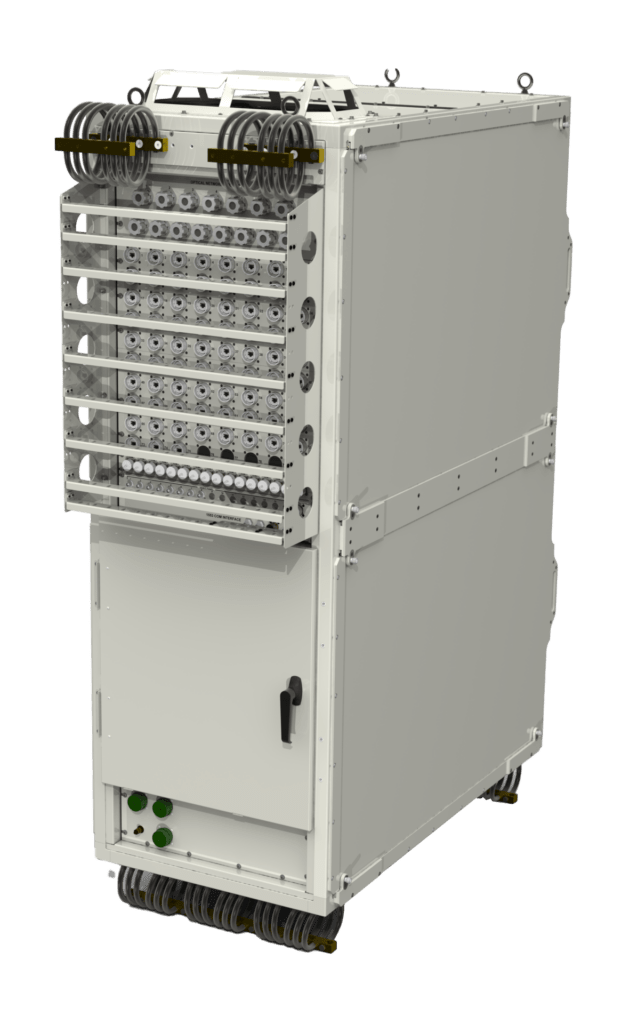

MIL-SPEC IT Cabinets

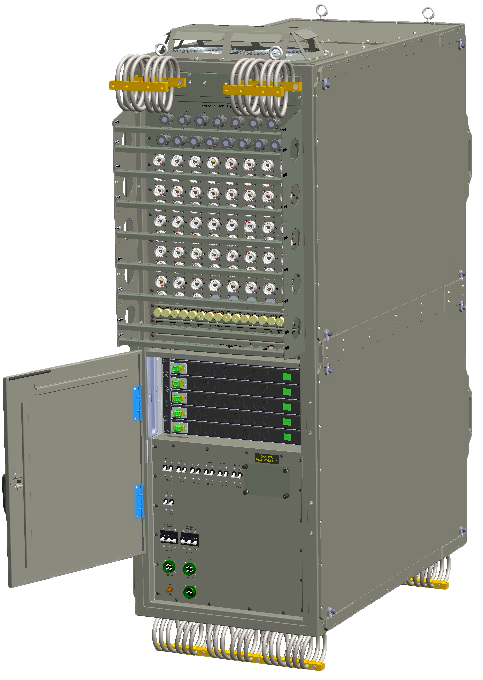

- Ruggedized and tested to be in compliance with MIL-STD-810G and MIL-STD-461F environmental and EMI requirements

- Constructed from 6082 Aluminum, making it ideally suited for both electrical conductivity and earthing through grounding bars and bonding straps

- Specifically designed to allow for straightforward attachment of aluminum, stainless steel, or other paneling material to its framework to create a modular cabinet

- The aluminum framing design offers lightweight construction with heavy-duty abilities. It comprised of aluminum-extruded members, matching die-cast and forged corners, and complementary components and fixings

- The components inside the cabinets are COTS in their nature

- Doors are hinged and can be completely removed for easy access. The doors, when closed provide protection against harsh environmental and EMI conditions

- Designed for easy maintenance and are easy to operate. Installation/dismantling of all components is possible by removable side panels. Design takes into account human engineering aspects to allow easy and comfortable use for technicians to maintain and operate the cabinet

- Cabinets design supports three types of equipment installation:

- Equipment mounted directly on slides

- Equipment mounted on 19” tray with slides

- Equipment mounted directly on 19” infrastructure

- For every equipment installation location, a cable retractor or other means of cable management is provided as well

- The Cabinets will be isolated from outer shocks and vibrations by means of robust, wire-type Shock Isolators

- Cooling is achieved by high flow fans. An optional, side mounted, closed-loop water-cooled heat exchanger can be offered as well.

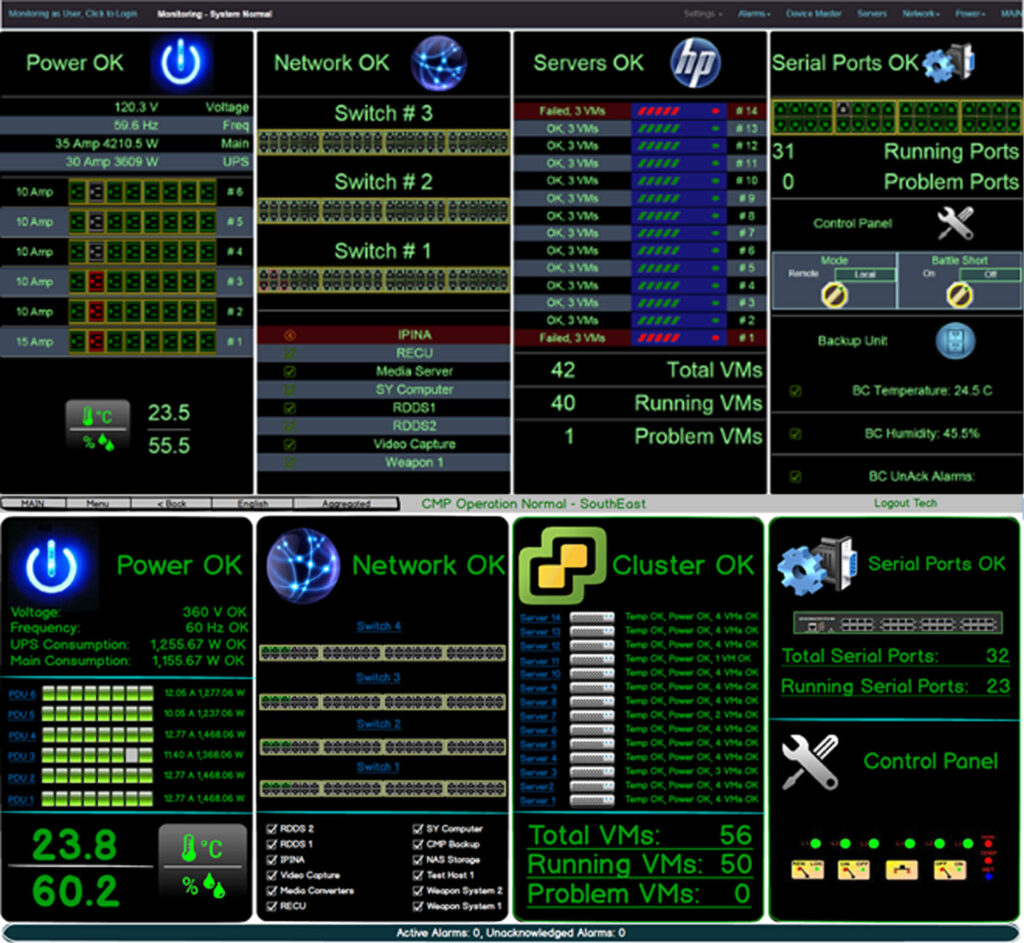

- Power is distributed via Power Distribution Units (PDU). Each outlet on the PDU is switched and can be externally controlled and monitored by the Cabinet Management Program (CMP) through LAN or RS-232 serial interface

- The cabinet is provided with an Environmental Monitoring Unit (EMU), which contains temperature/humidity sensors

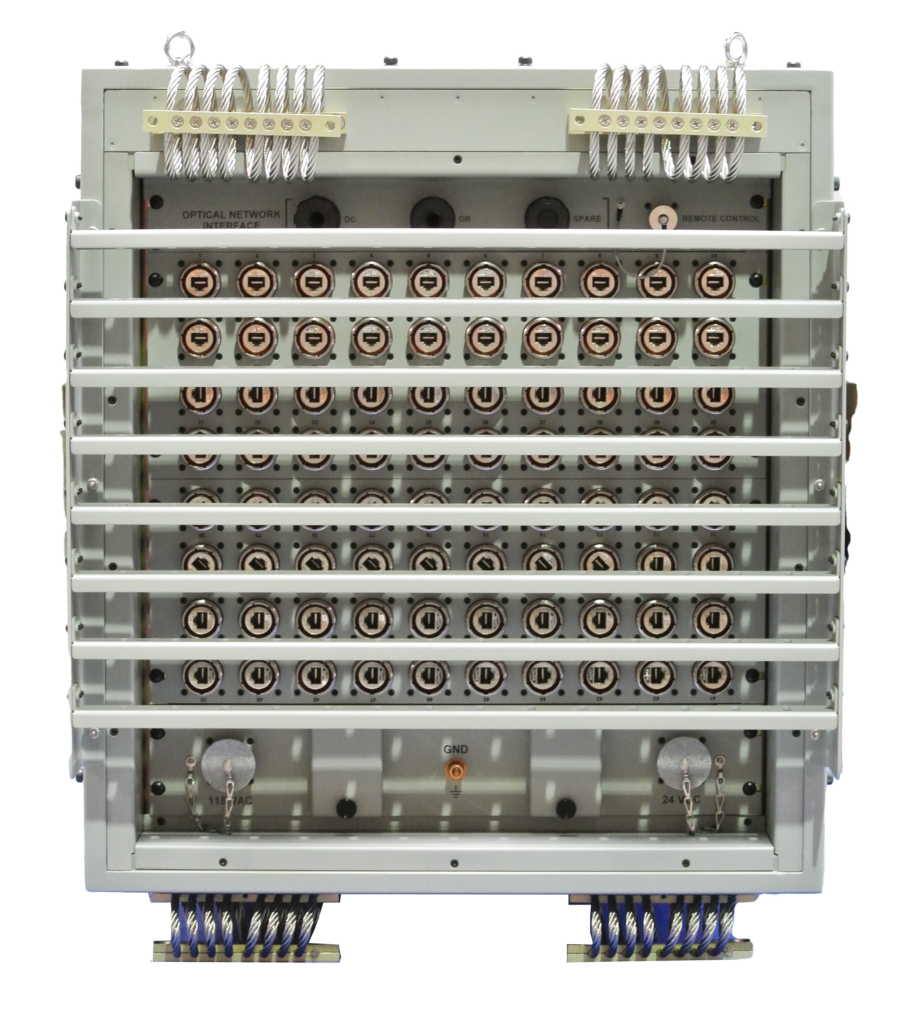

- All I/O interfaces are accomplished through an I/O connector’s panel. A set of mating connectors with appropriate back-shells and strain-reliefs can be offered as well